Astec Cold Feed Bins

Overview

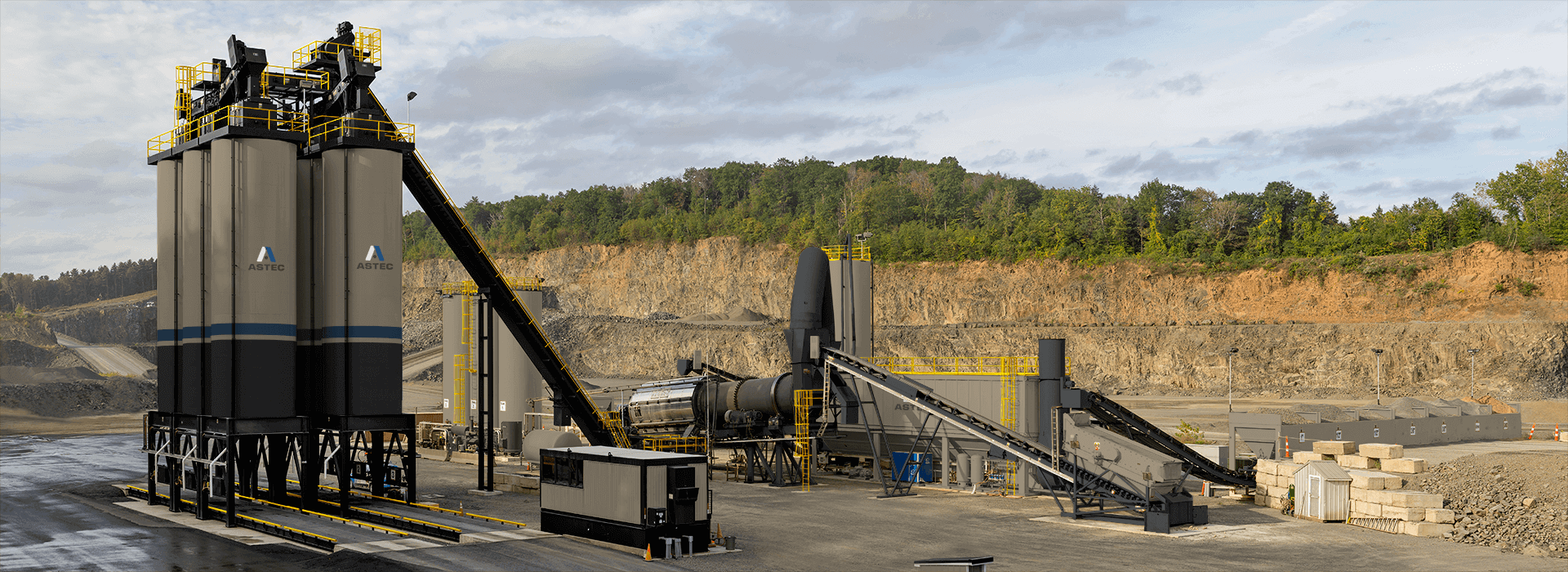

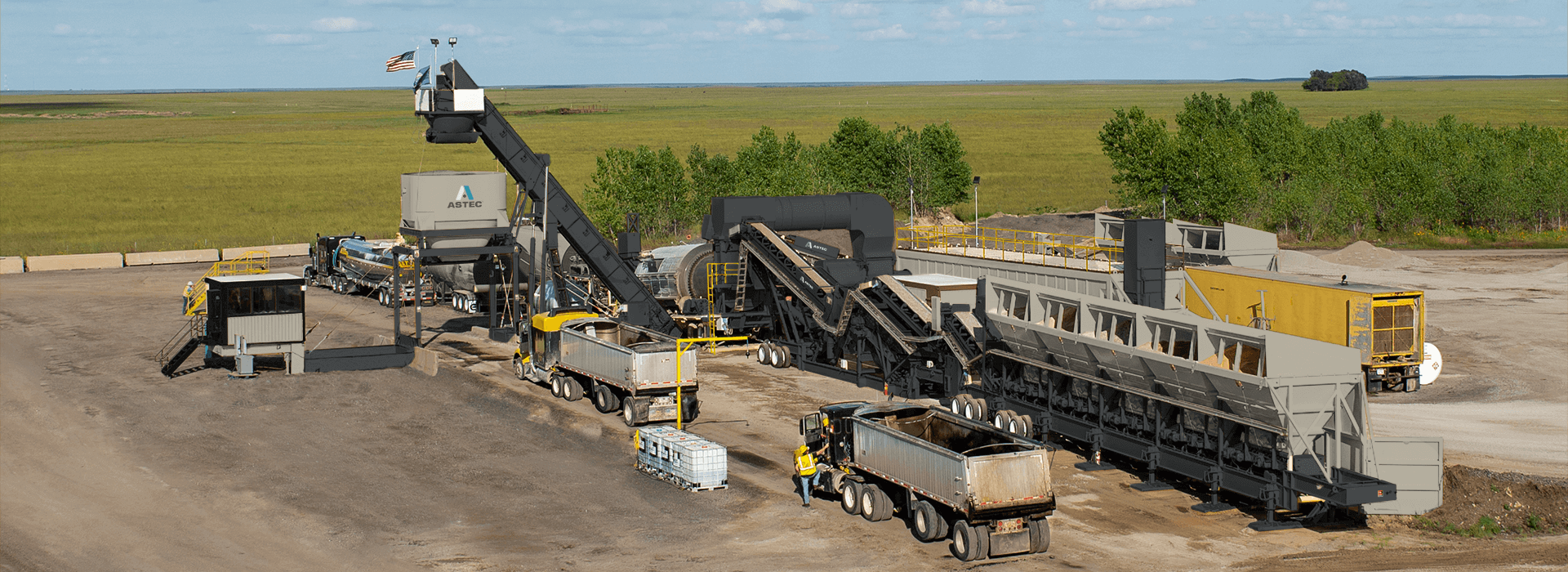

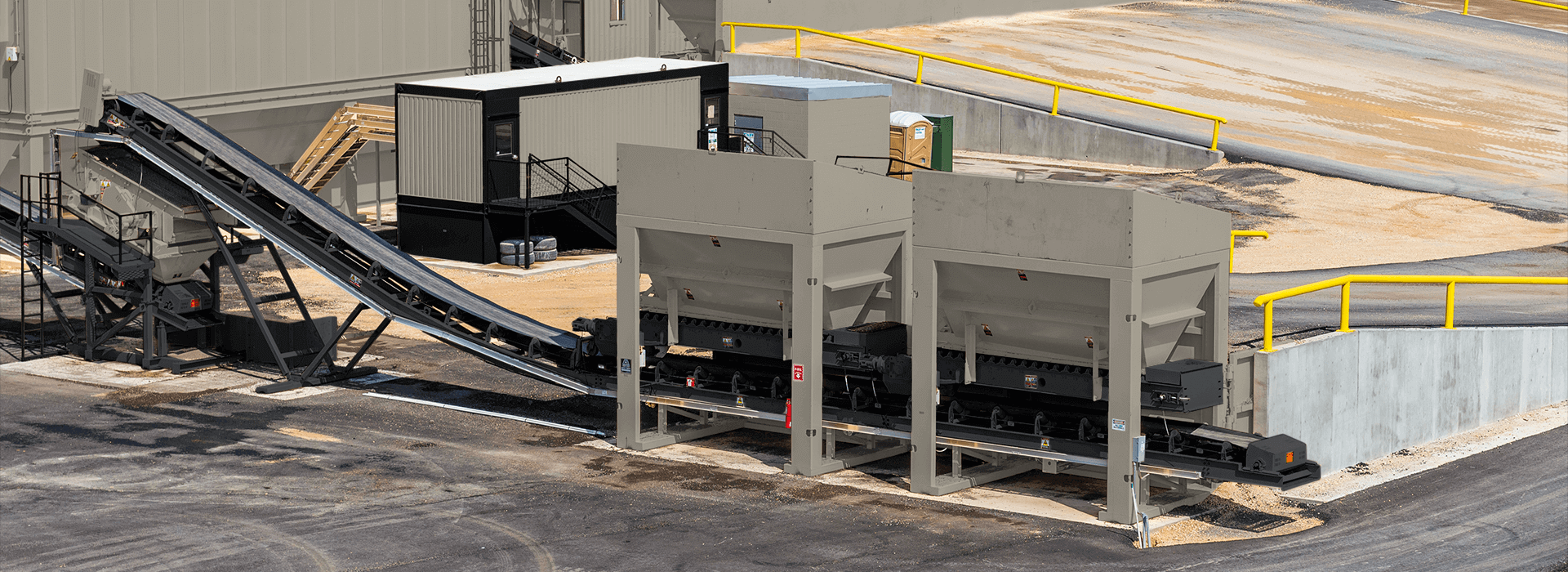

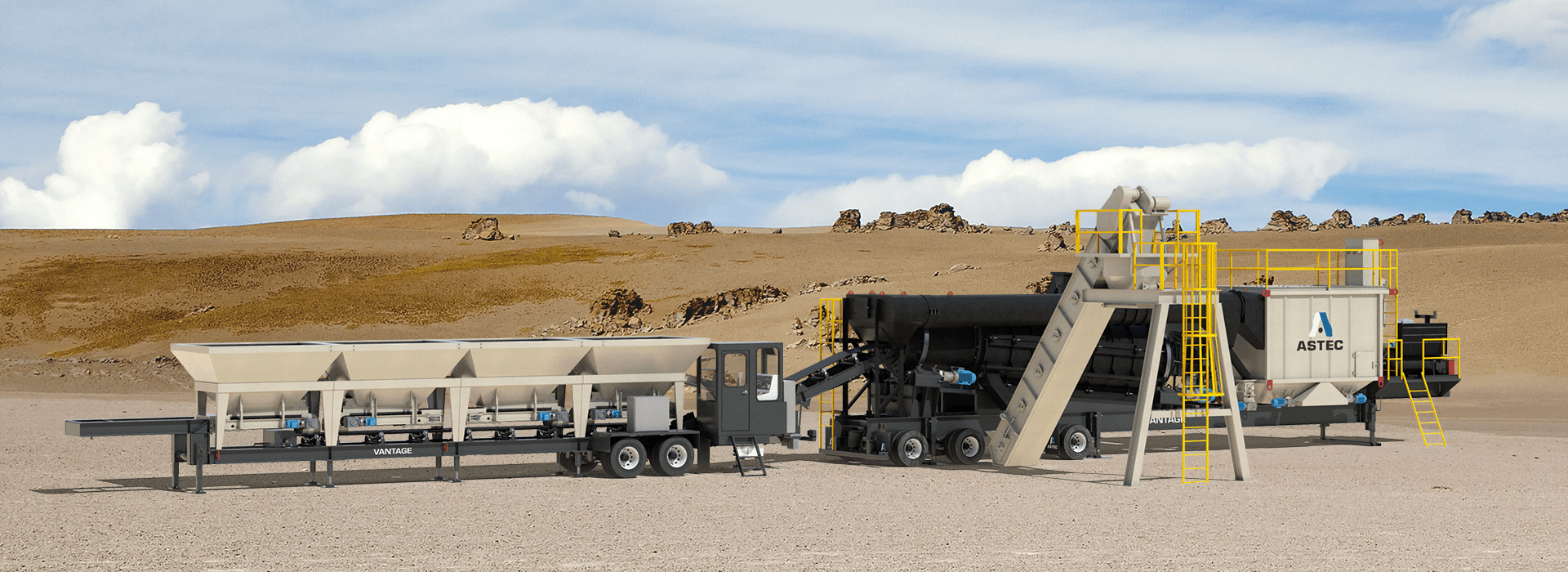

Astec cold feed bins are built to provide many years of service in demanding environments

All parts of Astec's cold feed bins, from the bins themselves to the steel bulkheads and foundations, are fabricated to perform and stand up to front-end loaders and abrasive materials year after year.

Features such as the protected walkway access at the backside of the belt feeders, steeper bins with better flow and cable trays on portable and relocatable bins give you even more value for your money. Astec designs and manufactures bins to be the most durable, productive and user-friendly.

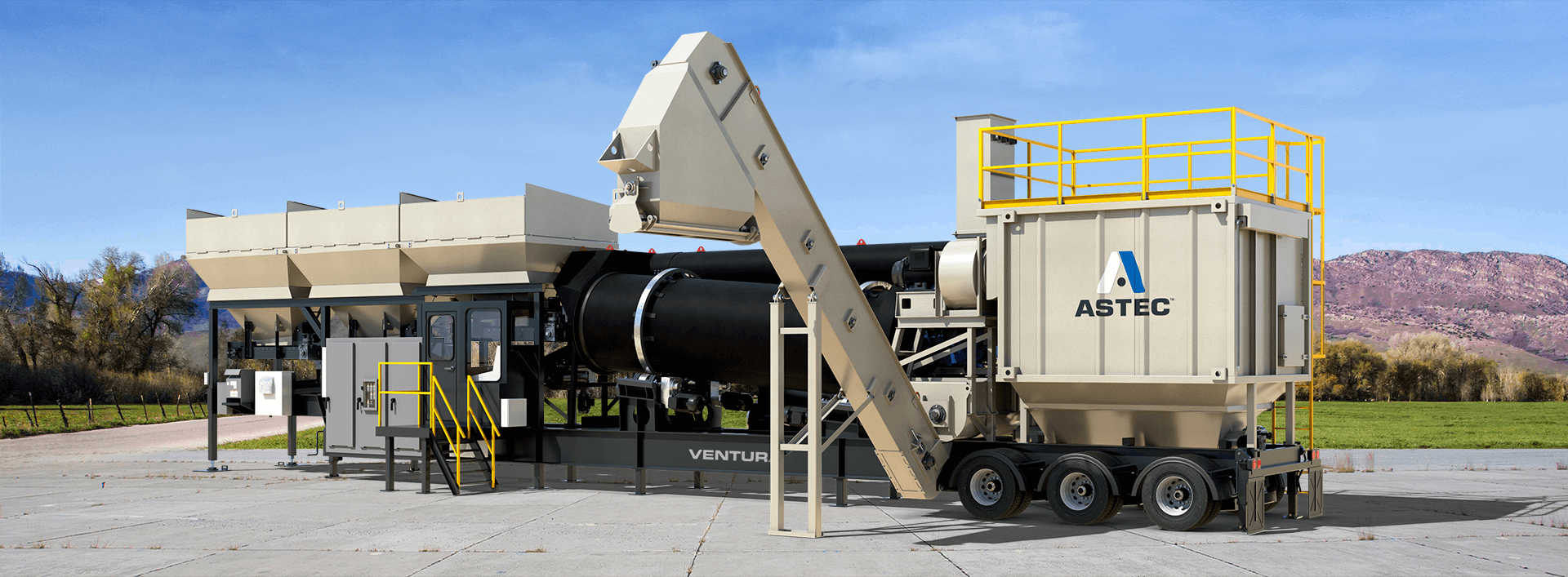

Astec offers stationary systems, relocatable modular systems and self-contained portable systems.

Applications

-

![]()

Asphalt Mixing

A thermal mixing process is required to turn aggregates and liquid AC into an asphalt pavement mix for road construction. This makes an asphalt mixing plant necessary for road construction. The complete line of Astec asphalt mixing plants, and its range of capacities and features, gives you the choices and flexibility to create your optimum solution.Learn More