Astec Warm Mix System

Overview

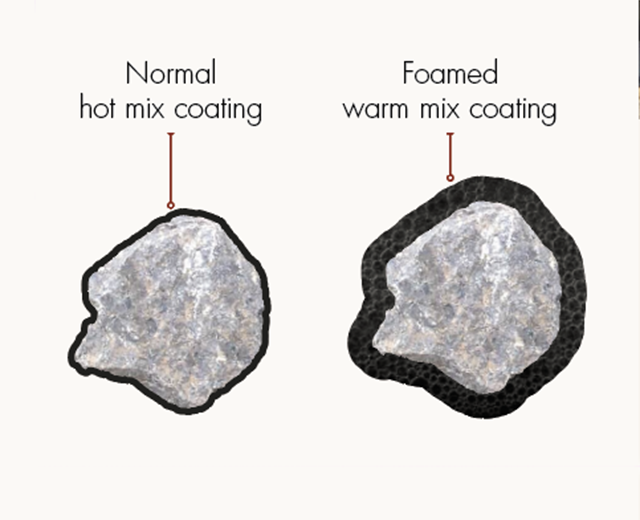

The benefits of warm mix asphalt, such as reduced energy consumption, lowered emissions, and elimination of visible smoke, are well-known in the asphalt paving industry. Warm mix technology allows mix to be prepared and placed at lower temperatures than conventional hot mix. To achieve this, the viscosity of the liquid asphalt cement (AC) must remain low at the reduced temperatures. Maintaining a low viscosity at lower temperatures allows mix to flow freely through storage, transfer, and placement equipment and is more easily compacted.

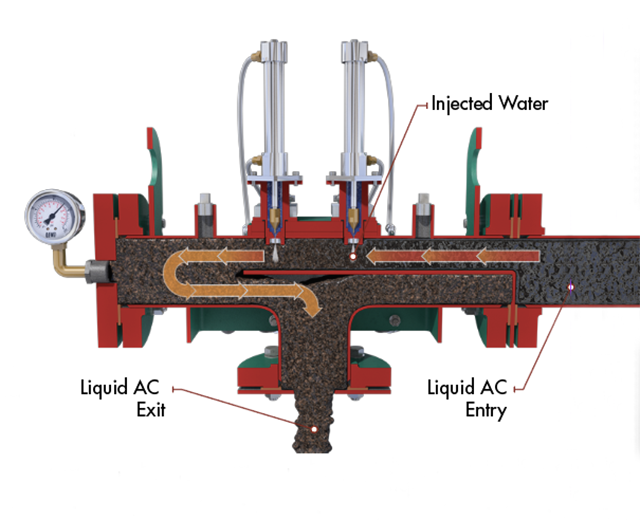

The Astec warm mix system achieves a lower temperature at a lower cost by eliminating the need for additives or special asphalt cement. Instead, the Astec warm mix system injects a small amount of water into the liquid AC to create microscopic steam bubbles. These small bubbles act to reduce the viscosity of the liquid AC, allowing the mix to be worked at lower temperatures.

Astec Warm Mix System

Applications

-

![]()

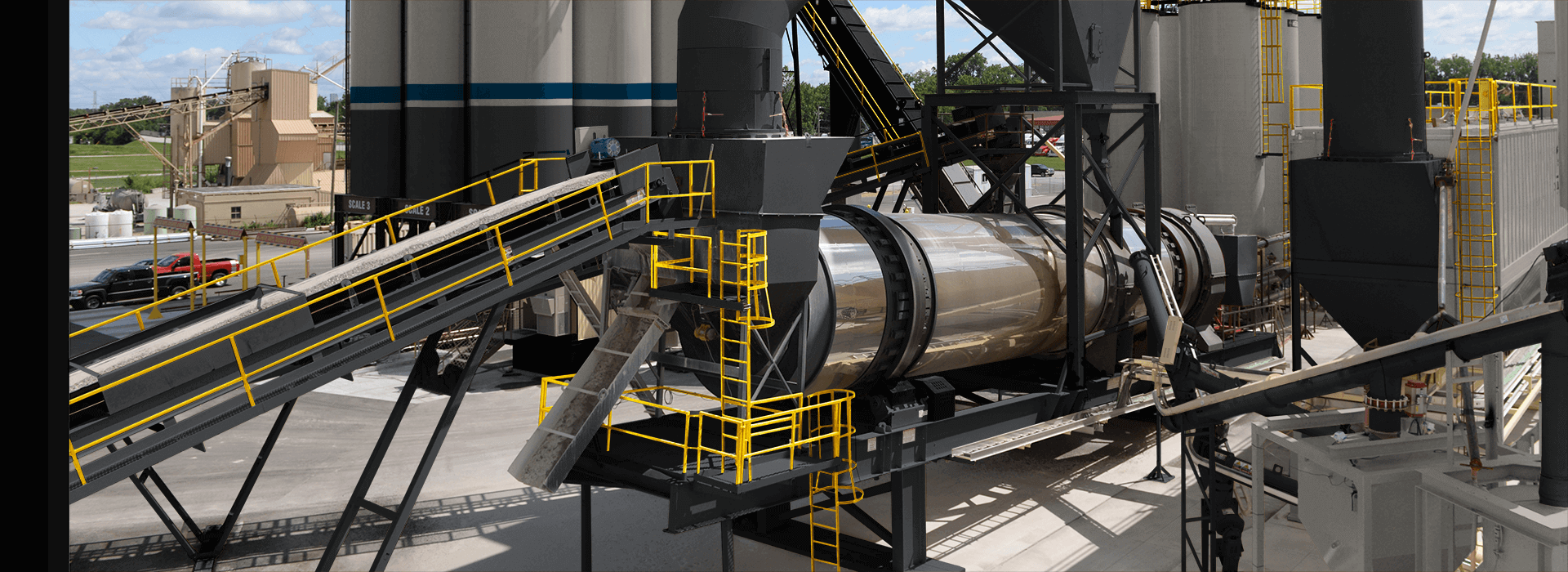

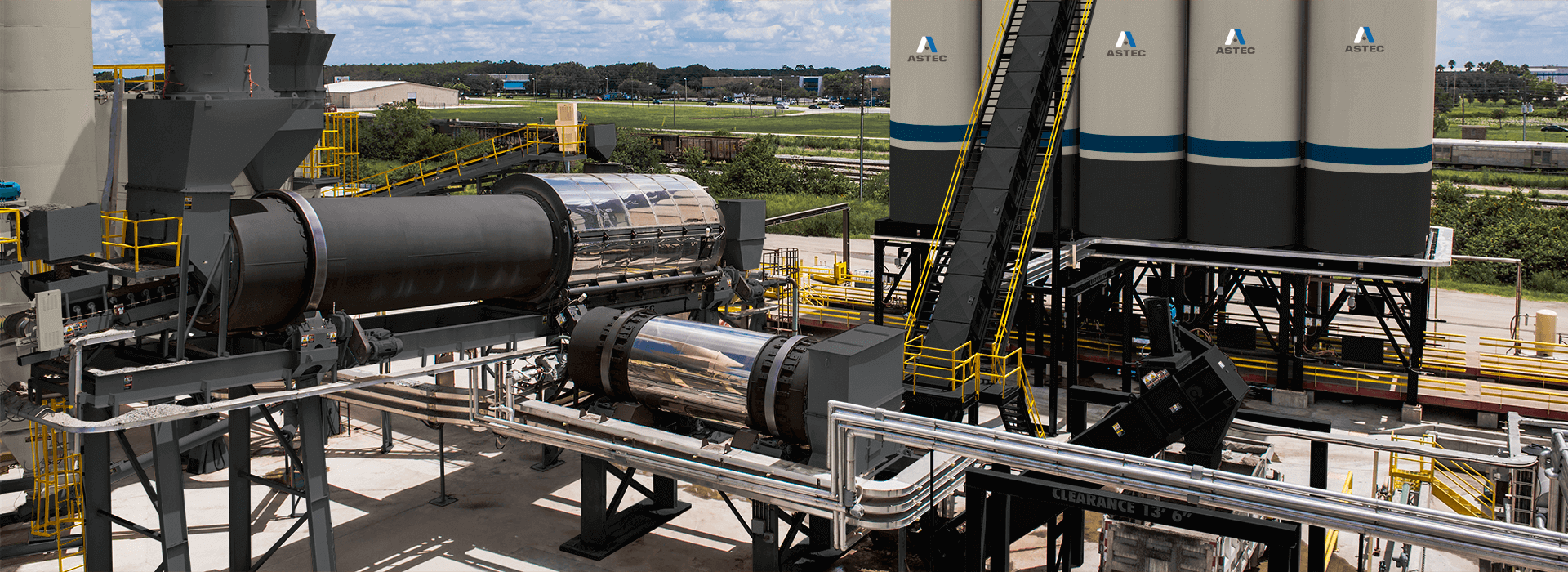

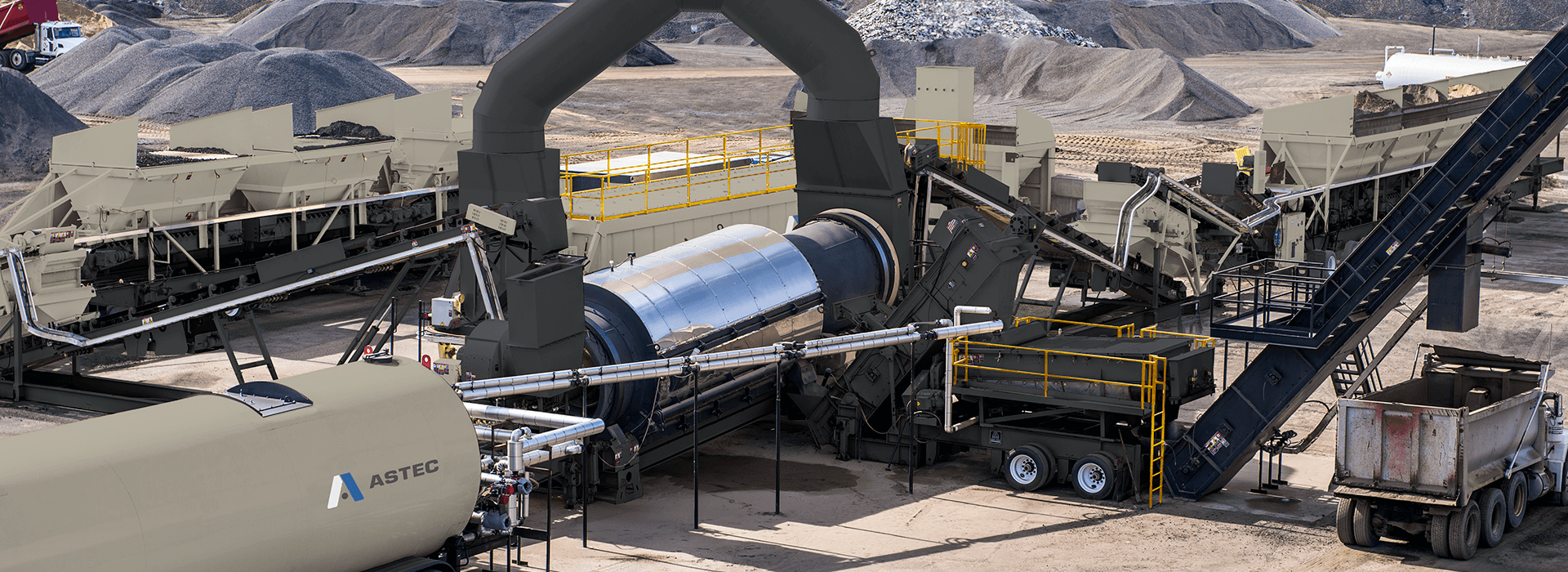

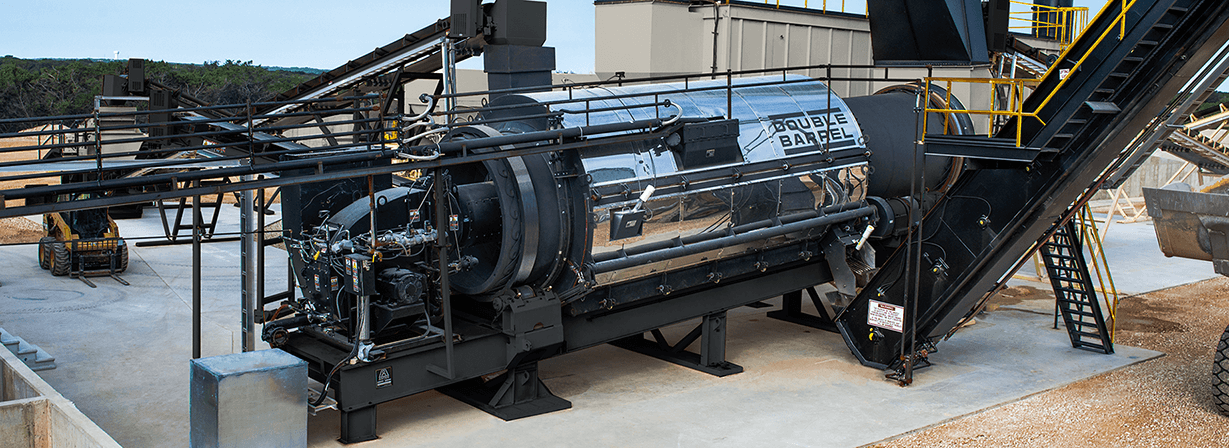

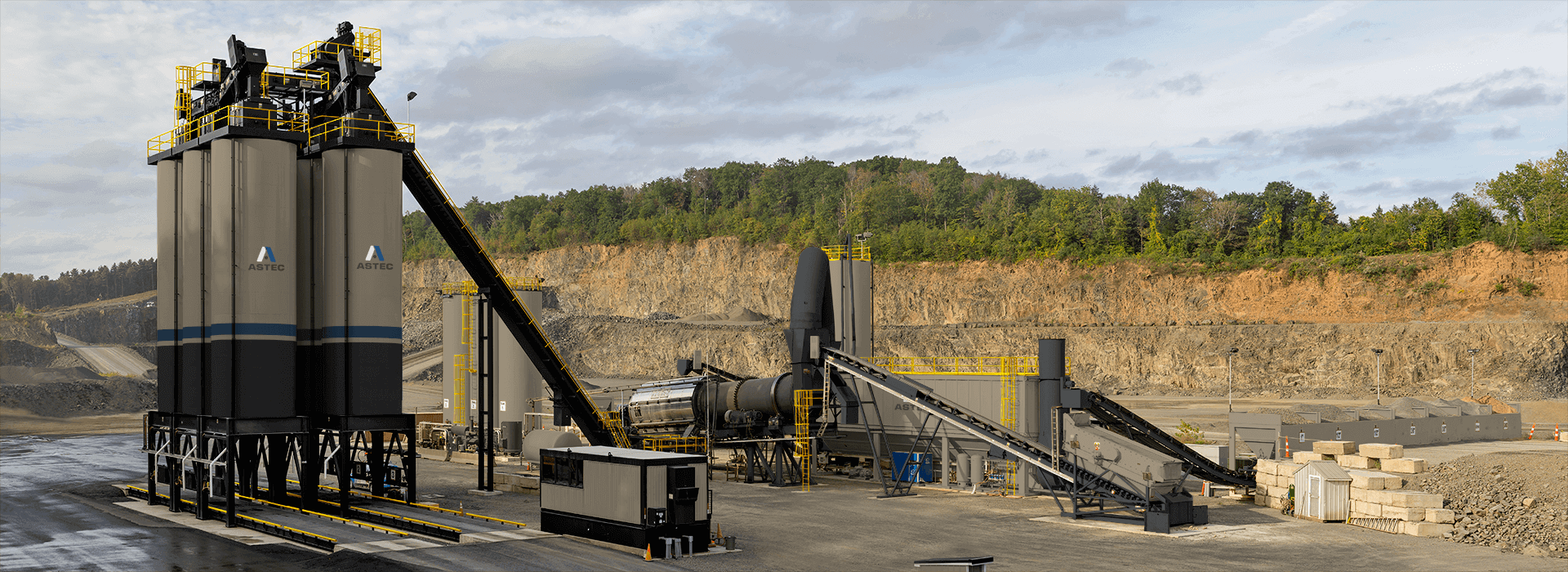

Asphalt Mixing

A thermal mixing process is required to turn aggregates and liquid AC into an asphalt pavement mix for road construction. This makes an asphalt mixing plant necessary for road construction. The complete line of Astec asphalt mixing plants, and its range of capacities and features, gives you the choices and flexibility to create your optimum solution.Learn More -

![]()

Aggregates

There are two main classes of aggregates: natural and manufactured. Deleterious material needs to be removed from both classes. Processing these materials typically requires various steps including reduction and sizing and also may include dewatering and sorting. Producers can use a variety of crushing, screening, dewatering and conveying equipment to meet their desired specifications.Learn More

/ranger-plants/ranger-line-header-02.jpg?sfvrsn=c145462e_5)